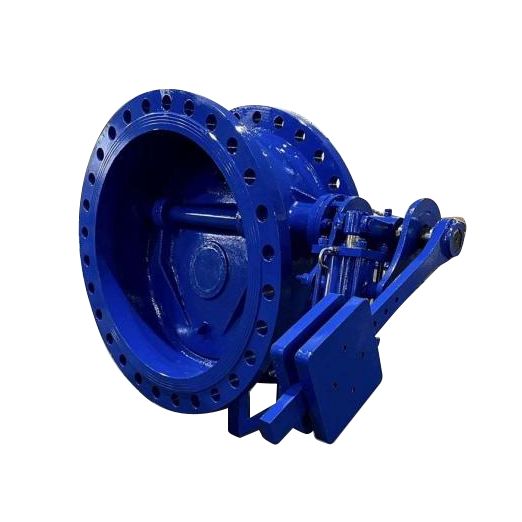

Tilting Type Check Valve

FYL's tilting type check valve is a high-quality product with a compact overall design, which is very convenient to install and use. We have rich experience in the design and manufacture of hydraulic machinery and equipment. Professionals will also conduct strict tests on the sealing of the products to ensure that the valve is leak-free.

Send Inquiry

The tilting type check valve is usually installed on the outlet pipes of pressurized water pumps in industrial circulation water supply and drainage, urban water supply and drainage, high-rise buildings, sewage treatment, hotels, etc. to prevent the backflow of the medium and eliminate destructive water hammer.

After so many years of development, FYL has also kept pace with the times in product design, constantly pioneering and innovating, and fully considering the requirements of various use environments. The tilting type check valve is made to run without vibration and noise, providing a smooth use experience and extending the service life.

Feature

● The tilting type check valve has a small structure, light weight, is a compact valve, and is easy to maintain and operate.

● As a hydraulic buffer device, the design of the tilting type check valve is based on a reasonable basis, and has been pioneered and innovated, with more stable and reliable performance. Because its installation position is outside the pipeline, it can better avoid contaminating the medium.

● There is no vibration or noise during the operation of the valve, and the experience is better.

● In the eccentric structure of the tilting type check valve, the structural parameters have been tested and adjusted by our professionals for many times, and finally determined to be the optimal value, which is conducive to flow resistance and vibration, and reduces the impact of water hammer.

● The tilting type check valve can achieve complete sealing and no leakage. It has undergone our strict testing process before leaving the factory to ensure your smooth use.

● The closing method and slow closing time of the tilting type check valve have a large adjustment range, and can be used under the requirements of different working conditions, with little restriction.

Performance Specifcation

|

Nominal Pressure |

working pressure |

Strength pressure |

Seal pressure |

|---|---|---|---|

|

MPa |

Mpa |

Mpa |

|

|

PN6 |

≤0.6 |

0.9 |

0.66 |

|

PN10 |

≤1.0 |

1.5 |

1.1 |

|

PN16 |

≤1.6 |

2.4 |

1.76 |

|

PN25 |

≤2.5 |

3.75 |

2.75 |

|

PN40 |

≤4.0 |

6 |

4.4 |

|

Medium |

Water, water vapor, air containing a small amount of dust, etc. |

||

|

Temperature |

<80℃ |

||

Main connection dimensions

Main connection size

|

DN |

L |

D |

D1 |

n-Φd |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 |

PN10 |

PN16 |

PN25 |

||

|

200 |

230 |

340 |

340 |

360 |

295 |

295 |

310 |

8-22 |

12-22 |

12-26 |

|

250 |

250 |

395 |

405 |

425 |

350 |

355 |

370 |

12-23 |

12-28 |

12-30 |

|

300 |

270 |

445 |

460 |

485 |

400 |

410 |

430 |

12-23 |

12-28 |

12-30 |

|

350 |

290 |

505 |

520 |

555 |

460 |

525 |

490 |

16-23 |

16-28 |

16-30 |

|

400 |

310 |

565 |

580 |

620 |

515 |

585 |

550 |

16-28 |

16-31 |

16-33 |

|

450 |

330 |

615 |

640 |

670 |

565 |

650 |

600 |

20-28 |

20-31 |

20-36 |

|

500 |

350 |

670 |

715 |

730 |

620 |

770 |

660 |

20-28 |

20-37 |

20-36 |

|

600 |

390 |

780 |

840 |

845 |

725 |

840 |

770 |

20-31 |

24-37 |

20-39 |

|

700 |

430 |

895 |

910 |

960 |

840 |

950 |

875 |

24-31 |

24-40 |

24-42 |

|

800 |

470 |

1015 |

1025 |

1085 |

950 |

1050 |

990 |

24-34 |

28-40 |

24-38 |

|

900 |

510 |

1115 |

1125 |

900 |

1050 |

1170 |

1090 |

28-34 |

28-40 |

28-48 |

|

1000 |

550 |

1230 |

1255 |

1320 |

1160 |

1390 |

1210 |

28-37 |

32-49 |

28-56 |

|

1200 |

630 |

1455 |

1485 |

1530 |

1380 |

1590 |

1420 |

32-40 |

36-49 |

32-56 |

|

1400 |

710 |

1675 |

1685 |

1755 |

1590 |

1820 |

1640 |

36-43 |

40-55 |

36-62 |

|

1600 |

790 |

1915 |

1930 |

1975 |

1820 |

|

1860 |

40-48 |

|

|

|

1800 |

870 |

2115 |

|

|

|

|

|

|

|

|