What Makes the Circulating Mechanical Bar Screen an Essential Equipment for Modern Wastewater Treatment?

2025-10-22

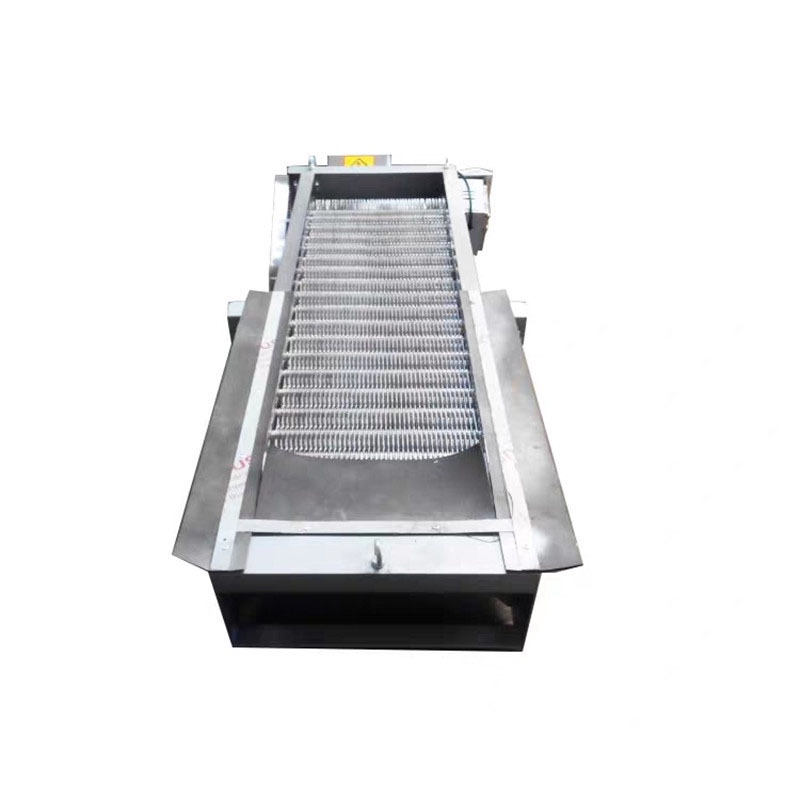

In wastewater treatment systems, efficiency and reliability are key to maintaining a clean, sustainable environment. The Circulating Mechanical Bar Screen has emerged as a vital piece of equipment for screening and removing solid waste from water flow before it enters further treatment stages. Designed for automatic operation and continuous circulation, this system effectively protects downstream pumps, pipelines, and other treatment units from clogging and damage.

At Tianjin FYL Technology Co., Ltd., we specialize in manufacturing high-performance Circulating Mechanical Bar Screens engineered for various applications, including municipal wastewater treatment plants, industrial effluent systems, and power stations. Our equipment combines advanced mechanical design with durable materials, ensuring long service life and minimal maintenance.

What Is a Circulating Mechanical Bar Screen and How Does It Work?

A Circulating Mechanical Bar Screen is a type of automatic screening device installed at the water inlet of sewage treatment facilities. Its main function is to intercept floating and suspended solids such as plastic bags, rags, branches, and paper scraps from raw wastewater.

The device operates through a circulating chain system equipped with rake teeth (bars). These rake teeth continuously rotate along the track, grabbing debris from the water and lifting it to the discharge outlet. Once there, the waste is cleaned off and transported for disposal, while the rake chain returns to the bottom of the channel to repeat the cycle.

This continuous circulation mechanism ensures uninterrupted operation, reducing manual labor and improving overall system reliability.

What Are the Main Features and Advantages?

-

High Automation: Fully automatic operation with continuous screening and debris removal.

-

Low Maintenance: Simple structure and wear-resistant materials ensure long-term stability.

-

Wide Application Range: Suitable for municipal, industrial, and agricultural wastewater systems.

-

Customizable Design: Available in different sizes, materials, and configurations to match specific flow rates and installation needs.

-

Energy-Efficient: Optimized transmission system reduces energy consumption.

-

Corrosion Resistance: Stainless steel components provide excellent durability in harsh environments.

What Are the Technical Parameters of the Circulating Mechanical Bar Screen?

Below is a summary of key specifications for our Circulating Mechanical Bar Screen models from Tianjin FYL Technology Co., Ltd.

| Parameter | Specification Range | Description |

|---|---|---|

| Channel Width | 500–3000 mm | Customizable according to installation site |

| Bar Spacing | 5–50 mm | Adjustable based on debris size requirements |

| Screen Angle | 60°–90° | Inclined design for smooth debris removal |

| Chain Speed | 1–5 m/min | Ensures efficient circulation and operation |

| Motor Power | 0.75–5.5 kW | Energy-saving and high-efficiency motors |

| Material Options | Carbon steel, Stainless steel (304/316) | Suitable for various environmental conditions |

| Control System | Automatic / Manual | PLC control available for advanced automation |

| Debris Discharge | Continuous automatic discharge | Reduces manual cleaning workload |

This technical design ensures that the Circulating Mechanical Bar Screen operates efficiently under a wide range of flow conditions and debris loads.

Why Is the Circulating Mechanical Bar Screen Important in Wastewater Management?

Solid waste is one of the main causes of operational issues in wastewater treatment facilities. Without effective screening, debris can block pumps, damage pipelines, and reduce treatment efficiency.

The Circulating Mechanical Bar Screen serves as the first line of defense, removing solid impurities from the water before they enter subsequent treatment processes. This not only protects equipment but also reduces the maintenance frequency and operational costs of the entire system.

By installing a reliable bar screen system, treatment facilities can achieve smoother operation, extend equipment lifespan, and improve the overall quality of treated water.

How Does the Circulating Mechanical Bar Screen Improve Environmental Sustainability?

Wastewater treatment is a cornerstone of environmental protection. The Circulating Mechanical Bar Screen contributes significantly by preventing large-scale debris from entering water bodies and minimizing environmental pollution.

Additionally, by automating the screening process, it reduces the need for manual cleaning, which enhances workplace safety and efficiency. When combined with energy-saving motors and corrosion-resistant materials, it becomes a sustainable solution aligned with modern environmental standards.

What Are the Common Applications of a Circulating Mechanical Bar Screen?

-

Municipal Wastewater Treatment Plants – Primary screening for domestic sewage.

-

Industrial Wastewater Treatment – Handling waste from food, textile, paper, and chemical industries.

-

Power Plants – Cooling water intake protection.

-

Irrigation Systems – Preventing blockages in canals and pipelines.

-

Flood Control Stations – Screening debris during heavy rain or stormwater flow.

Whether used in a city's sewage network or an industrial discharge system, the Circulating Mechanical Bar Screen provides efficient, continuous, and reliable screening performance.

How to Choose the Right Circulating Mechanical Bar Screen for Your Project?

Selecting the right model depends on several factors:

-

Water Flow Rate and Channel Width – Determines the overall size and design.

-

Type and Volume of Debris – Influences the spacing between bars.

-

Installation Environment – Corrosive or non-corrosive conditions affect material selection.

-

Automation Level – Decide between basic motor-driven or PLC-controlled systems.

-

Maintenance Requirements – Consider systems with easy access for inspection and repair.

At Tianjin FYL Technology Co., Ltd., our engineers provide complete technical support to help you customize a system that meets your operational needs and site conditions.

FAQ About Circulating Mechanical Bar Screen

Q1: What is the main function of a Circulating Mechanical Bar Screen?

A1: Its main function is to intercept and remove floating and suspended solids from wastewater, preventing downstream clogging and ensuring the smooth operation of pumps and treatment systems.

Q2: How often does the Circulating Mechanical Bar Screen require maintenance?

A2: With its durable construction and automatic cleaning system, maintenance is minimal. Regular inspections every few months are sufficient to ensure optimal performance.

Q3: Can the Circulating Mechanical Bar Screen be customized for different projects?

A3: Yes. At Tianjin FYL Technology Co., Ltd., we offer full customization options including screen width, bar spacing, materials, and control systems to meet your specific requirements.

Q4: What materials are recommended for corrosive wastewater environments?

A4: For corrosive conditions such as chemical or industrial wastewater, stainless steel 304 or 316 is recommended to ensure long-term resistance and durability.

Why Choose Tianjin FYL Technology Co., Ltd.?

With years of experience in wastewater treatment equipment manufacturing, Tianjin FYL Technology Co., Ltd. is known for delivering reliable, innovative, and cost-effective screening solutions. Our Circulating Mechanical Bar Screen systems are trusted by clients across municipal, industrial, and environmental projects worldwide.

We are committed to providing high-quality products supported by technical expertise, prompt after-sales service, and complete installation guidance.

For more information about the Circulating Mechanical Bar Screen or to request a customized quotation, please contact at Tianjin FYL Technology Co., Ltd.